This is one of three articles on stock management in Dynamics 365. In the first of three articles I will focus on the Item Model group property and how it affects inventory transactions. This key field is setup against the item in the general tab of the items details. This setting or property will determine the how your inventory or stock transactions will be manged on both the issuing of stock via a sales order or the receipt of stock via a purchase order.

It will also govern how the product will be affected by stock adjustments or any other transaction which affect the stock levels of an item.

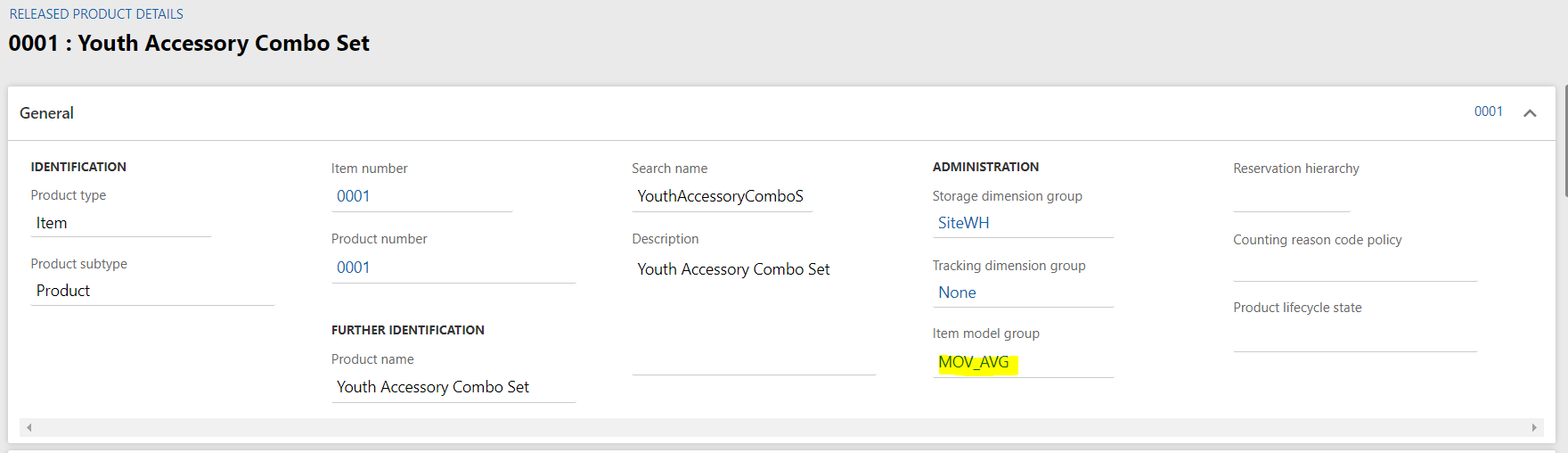

Below is an example from Contoso retail for product 0001. This item has an Item Model group set up for MOV_AVG.

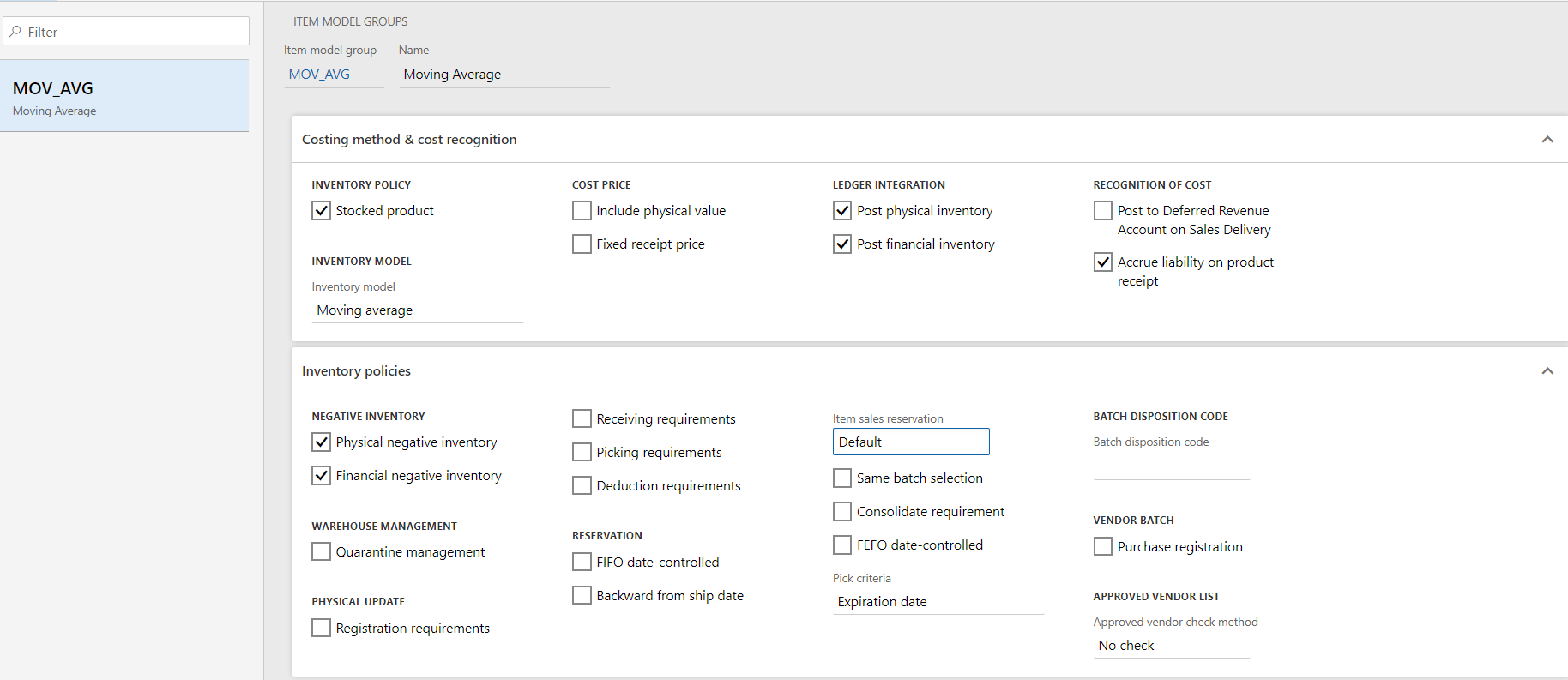

Clicking on the model group hyperlink or fastlink will bring you into the form for managing the properties for this item model group. The Item model group is displayed below for MOV_AVG.

What do all the specific options mean and how do they affect the item they are assigned to.

Cost method and cost recognition explained

Inventory Model-This field is a selection of inventory models that determines the item cost price. This is the most important setting used to value the stock in your warehouse. Options include “moving average”, FIFO (first in and first out) and LIFO (last in and first out).

Stock Product is selected if we will be holding stock or inventory for this item. Service items, items which do not involve the management of stock, like call out charges or product services would be an example of this type of product.

Include physical value- This would apply to the calculation of the average cost price of the stock. Do we want the physically updated quantity and value in calculation of average cost price? This would apply to items that have not been financially updated, so no invoices received for this item we would still include the value of this stock in the average price.

Fixed Receipt Price- This setting will adjust item receipts to a standard cost price. Select this option to adjust issues and receipts to a fixed receipt price. The fixed receipt price is a principle for inventory valuation that sets the price of receipts to the active planned cost or basic cost of a product. The fixed receipt price is defined in the Price field on the Manage costs tab in the Released product details page.

Post physical inventory controls all posting of stock or inventory to be posted to the general ledger. This means physical stock movements will registered financially in the general ledger.

Post financial inventory controls all financial transactions related to stock or inventory to be posted to the general ledger. This means financial posting will registered financially in the general ledger.

There are two recognition of costs settings.

Post to deferred revenue account on Sales Delivery- This posting would occur on a shipment that has been packing slip updated but not invoiced.

Accrue Liability on product receipt- This occurs during a receipt where we post on product receive prior to invoicing.

Inventory policies explained

Negative Inventory – This applied to both financial and physical inventory. Negative Inventory manages whether the stock levels can go into the negative. This normally happens when issues happen in other parts of the business. Such as a purchase or sales not being in sync in your business. Issue happen and this setting may support your business process.

Quarantine Management- When an item is returned to the warehouse from say a customer return. This stock would automatically go to quarantine management before it’s available for resale. This item of stock would need to be released from quarantine before the item is available.

Consolidated Picking Method- With consolidated picking, multiple orders can be combined into one picking list. The orders can potentially be of different types, such as sales orders or transfer orders. Consolidated picking uses advanced shipment functionality, such as reservation via shipment, activate picking, activate pallet transport, and guided picking routes. Consolidated picking is optimized picking because there is one picking list for multiple orders. It is typically used in a warehouse management environment.

Physical update section of the item model group has four different options. These options determine what inventory status is required on your products before they can move on to further processing.

Registration requirements - Select this option to indicate that item receipts must be registered before inventory is physically updated. The status of the inventory transaction for the item receipt must be Registered before the item's product receipt is updated

Receiving Requirements - Select this option to indicate that item receipts must be physically updated before they can be financially updated. If you post a vendor invoice, a product receipt must be entered and posted before the vendor invoice for the product receipt can be posted.

Picking Requirements -Select this option to indicate that item issues must be picked before inventory is physically updated. The status of the inventory transactions for the item issue must be Picked before the packing slip is updated. This field is used by warehouse management. Picked items are part of physical inventory.

Deduction Requirements - Select this option to indicate that item deductions must be physically updated before they can be financially updated. If you post a vendor invoice, a product receipt must be entered and posted before the vendor invoice for the product receipt can be posted. The deducted quantity on the product receipt might differ from the negative invoiced quantity. In this case, an icon is displayed in the Product receipt quantity match field in the Vendor invoice page.

Reservation- This group of settings would control the way items get reserved off of expected receipts.

FIFO- Use this setting to activate a date-controlled reservation. If so, do we then want to look backward from our ship date. Select this option to reserve expected receipts, such as open purchase order lines, that have a date of receipt that is nearest to the delivery date of the sales order. If this option is cleared, incoming inventory transactions that have the earliest date of receipt are reserved. Items that are available in inventory are not controlled by the Backward from ship date parameter.

Item Sales Reservation- How do we want our sales orders to reserve items?

Same batch selection- Do we have restrictions on using the same batch or can we use multiples?

Consolidation requirement- Activated when same batch selection is marked. This will consolidate order lines for same batches.

FEFO- This will look at dates on batches

Pick Criteria- If FEFO is checked this determines if we use expiration or best before date.

Batch Disposition code- What is our batch disposition code coming into the system

Purchase Registration- do we want to add vendor batch details upon registration. This will involve details like country of origin etc.

Approved vendor check method- Do we want to set an approved Vendor check?